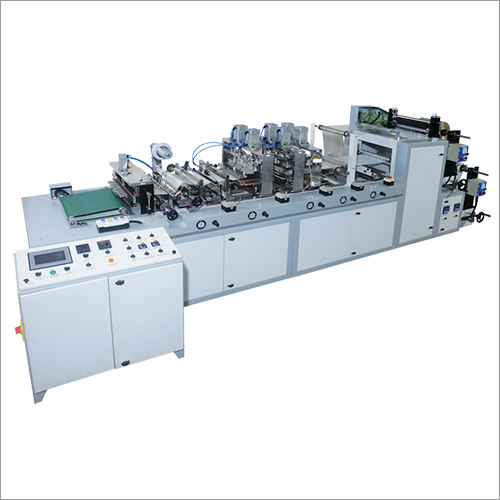

Surgical Pouch Machine

Surgical Pouch Machine Specification

- Voltage

- 220V/380V

- Control System

- PLC Controlled Touch Panel

- Frame Type

- Heavy Duty Steel

- Power Rating

- 4 kW

- Frequency

- 50/60 Hz

- Connectivity Options

- Ethernet/USB

- Cooling System

- Air Cooling

- Machine Type

- Automatic Surgical Pouch Machine

- Accuracy

- High Precision (+/- 1 mm)

- Production Capacity

- 60-100 Pouches/Min

- Motor Power

- 2.5 HP

- Operating Temperature

- 5C - 45C

- Noise Level

- Below 75 dB

- Model No

- SPM-2200

- Lubricating System

- Automatic

- Drive

- Electric

- Product Type

- Surgical Pouch Machine

- Technology

- Advanced Sealing & Cutting

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 4 kW

- Pressure

- Adjustable

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 2200 mm x 1050 mm x 1700 mm

- Color

- Grey & Blue

- Usage & Applications

- Medical Surgical Pouch Sealing

- Compressor Requirement

- 0.5 HP (if applicable)

- Maximum Sealing Width

- 450 mm

- Pneumatic Pressure

- 6 Bar (if applicable)

- Display Type

- HMI Touch Screen

- Machine Frame Material

- Stainless Steel & Mild Steel

- Film Thickness Range

- 0.02 mm 0.18 mm

- Service Support

- On-site & Remote

- Power Consumption

- 4 kW/h

- Minimum Order Quantity

- 1 Unit

- Packaging Type Supported

- Sterilization Pouch, Gusseted & Flat Pouch

- Ambient Humidity

- 90% RH non-condensing

- Product Contact Material

- Food & Medical Grade Stainless Steel

- Operator Interface

- Color LCD Panel

- Working Speed

- 60-100 Cycles/Min

- Bag Length Range

- 100 mm 500 mm

- Changeover Time

- Less than 10 min

- Sealing Type

- Impulse Heating

Surgical Pouch Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- Days

About Surgical Pouch Machine

Our company is known for making optimum quality surgical pouch machine. It is multitasking machine and makes it convenient to seal through a heated mould and collecting it after being cut by a slitting blade at a rewinding apparatus. In addition to this, our offering is the perfect tool for creating sterilisation packages like reels and self-adhesive pouches, which are widely utilised in the medical sector. Surgical pouch machine and a heat sealer made for use in the medical industry are the two primary parts of the procedure. Electronic synchronisation between the two devices allows the product to be deposited into the bag as soon as it is ready.

Product details

|

Cutter Function |

Pneumatic |

|

Heating Load |

4.0k.w |

|

Machine Color |

Vip Blue & Swan White |

|

Machine Height |

1870 Mm |

|

Machine Length |

3500 Mm |

|

Machine Width |

990 Mm |

|

Main Drive |

Servo Driven |

|

Maximum Machine Speed |

30-80 Pouches/min |

|

Maximum Roll Width |

400 Mm |

|

Minimum Roll Width |

50mm |

|

Number of Station [ Cutting ] |

One |

|

Number of Station [punching] |

One- for Thumb Nail |

|

Number of Station [sealing] |

One bottom,Two side Sealing |

|

Number of Unwinder [for Roll] |

Two- for Roll Mounting |

|

Sealer & Punching Function |

Pneumatic |

|

Servo Motor |

7.15 Nm |

|

Unwind Drive |

Synchronised to Main Drive |

|

Unwind Motor |

0.5 H.p |

|

Weight of Machine |

850 Kgs |

|

Country of Origin |

Made in India |

Precision and Performance

Achieve accurate sealing with high precision (+/- 1 mm) using advanced impulse heating. The machine operates at speeds up to 100 cycles per minute, ensuring optimal production capacity for busy medical environments. Its air cooling system maintains stable operating temperatures.

User-Friendly Control System

The color LCD HMI touch panel and PLC control make operating the machine simple and intuitive. Quick changeover times of less than 10 minutes boost efficiency while the automatic lubricating system reduces maintenance downtime.

Robust Design and Hygiene Assurance

Built with food and medical grade stainless steel, the SPM-2200s powder-coated, heavy-duty frame withstands rigorous use in sterile environments. All product contact parts adhere to strict hygiene requirements, suitable for surgical pouch packaging.

FAQs of Surgical Pouch Machine:

Q: How does the Surgical Pouch Machine ensure accurate and reliable sealing?

A: The machine utilizes impulse heating and PLC-controlled touch panel technology, achieving high sealing precision (+/- 1 mm). Its adjustable pressure mechanism allows for consistent sealing on varying film thicknesses ranging from 0.02 mm to 0.18 mm.Q: What types of pouches can be packed with this machine?

A: This surgical pouch machine supports sterilization pouches, as well as gusseted and flat pouch formats, catering to diverse packaging needs in medical and surgical applications.Q: When is it suitable to use the machine for medical packaging?

A: It is ideally used during the packaging of sterilized items in hospitals, clinics, and surgical supply facilities when high hygiene standards and rapid, precise production are required.Q: Where can this machine be installed and operated?

A: The machine is designed for installation in medical packaging lines, surgical supply manufacturing facilities, and distribution centers. Its electric drive and compact dimensions (2200 mm x 1050 mm x 1700 mm) enable flexible placement within existing process flows.Q: How long does it take to changeover between pouch formats?

A: The machine offers a rapid changeover process, with switching between formats typically taking less than 10 minutes, minimizing production downtime and enhancing workflow efficiency.Q: What are the benefits of using advanced technology and materials in this machine?

A: Utilizing advanced sealing and cutting technology with food and medical grade stainless steel ensures superior hygiene, durability, and consistent sealing quality. The automatic lubricating and air cooling systems help prolong machine life and maintain smooth operation.Q: What support options are available post-purchase?

A: The manufacturer provides both on-site and remote service support across India, assisting with installation, technical troubleshooting, and maintenance to ensure uninterrupted operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surgical Rolls Making Machine Category

Surgical Rolls Making Machine

Minimum Order Quantity : 1 Unit

Type : Packaging Line

Weight (kg) : 800 Kilograms (kg)

Automatic Grade : Automatic

Drive Type : Electric

Send Inquiry

Send Inquiry Send SMS

Send SMS