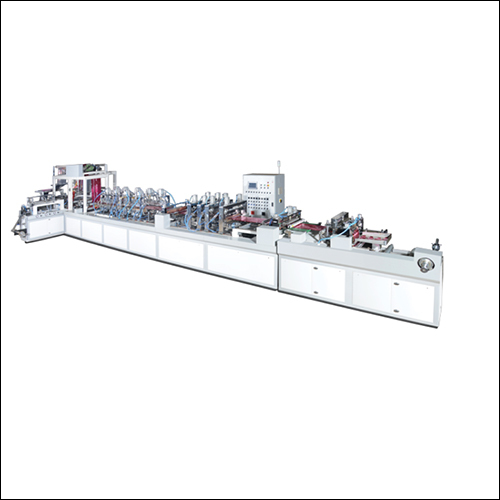

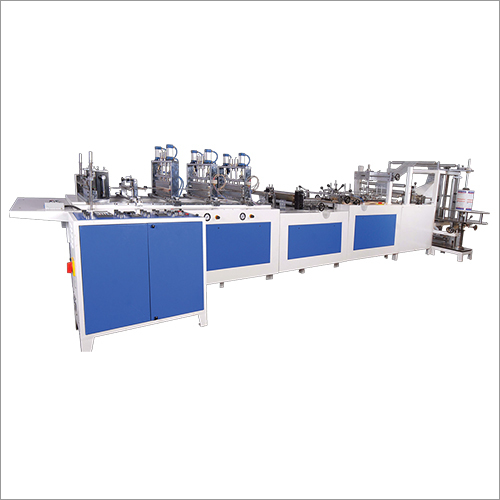

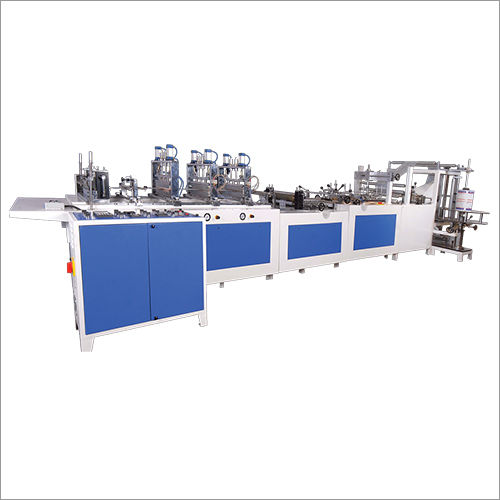

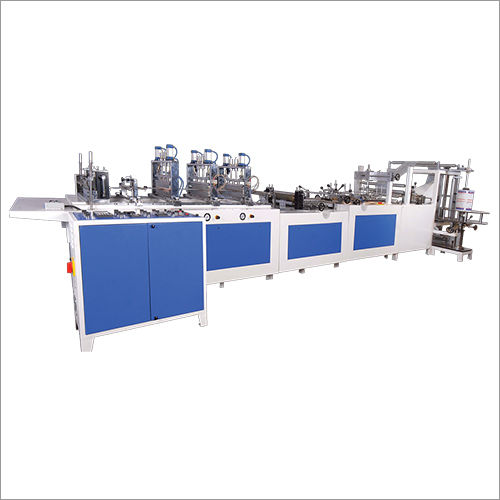

सà¥à¤à¥à¤à¤¡ ठप पाà¤à¤ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨

सà¥à¤à¥à¤à¤¡ ठप पाà¤à¤ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨ Specification

- टाइप करें

- स्टैंड अप पाउच मशीन

- मटेरियल

- स्टेनलेस स्टील

- फ़ीचर

- अन्य

- सहायक पैकेजिंग मशीन का प्रकार

- स्टेरिलिज़र

- स्वचालित ग्रेड

- ऑटोमेटिक

- कंट्रोल सिस्टम

- PLC नियंत्रण

- ड्राइव टाइप

- इलेक्ट्रिक

- रंग

- सफ़ेद

सà¥à¤à¥à¤à¤¡ ठप पाà¤à¤ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨ Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- 1 प्रति सप्ताह

- डिलीवरी का समय

- 7 दिन

About सà¥à¤à¥à¤à¤¡ ठप पाà¤à¤ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨

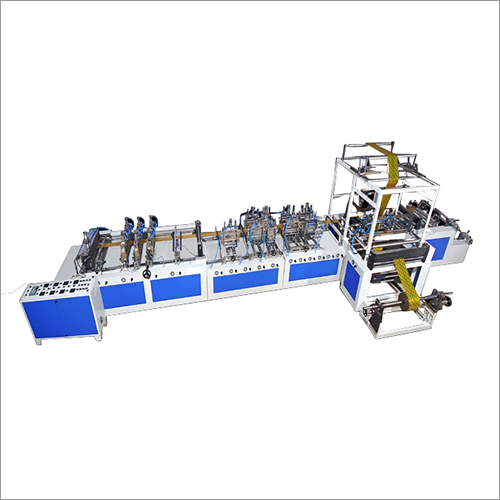

A stand-up pouch making machine is a type of packaging machinery used in the manufacturing of stand-up pouches. Stand-up pouches are flexible packaging containers that can stand upright on store shelves, making them popular for packaging a wide range of products, including food items, beverages, pet food, cosmetics, and more. These pouches are typically made from flexible materials such as plastic, foil, or a combination of materials.The stand-up pouch making machine automates the process of creating these pouches. Here are some key components and functions typically found in a stand-up pouch making machine: 1. Material Feeding: The machine feeds rolls of flexible packaging material, often called roll stock, into the manufacturing process. This material can be made of various layers, including plastic, aluminum foil, and paper, depending on the requirements of the final pouch.2. Printing: Some machines have integrated printing systems to add branding, product information, and designs directly onto the packaging material as its being processed.3. Lamination: If the pouches require multiple layers for barrier properties or aesthetics, the machine may include a lamination station to combine these layers.4. Heat Sealing: Heat sealing bars or rollers are used to create seals on the sides and bottom of the pouch. The type of seal (e.g., fin seal or lap seal) may vary depending on the pouch design.5. Cutting and Shaping: The machine cuts the sealed material into the desired pouch shape, which typically includes a top opening and the stand-up base.6. Gusseting: In some cases, the machine may include a gusseting station to create gussets or pleats at the bottom of the pouch, allowing it to expand and stand up when filled.7. Filling and Capping (Optional): In a production line, the pouches may be filled with the product (e.g., food, liquid) and then capped or sealed at the top.8. Inspection and Quality Control: Modern machines often include sensors and quality control systems to detect defects in the pouches and ensure consistent quality.9. Pouch Output: The finished stand-up pouches are typically stacked, bundled, or conveyed to downstream processes for packaging and distribution.Stand-up Pouch Making Machine Specifications: Number Of Station CuttingOneNumber Of Station Bottom SealTwoNumber Of Station Side SealFiveNumber Of Station ZipperOneNumber Of Station CoolerFourMinimum Web Width For 3 Side Seal200 MmMinimum Web Width For Standup Pouch250 MmMachine Length8400 Mm AproxMachine Width2800 Mm AproxMachine Height1850 Mm AproxMaximum Pouch Size For StandupHeigth 400 Mm X Width 300 MmMinimum Pouch Size For StandupHeigth 100 Mm X Width 75 MmMaximum Pouch Size For 3side SealLength 400 Mm X Width 500 MmMinimumpouch Size For 3 Side SealLength 100 Mm X Width 100 MmMaximum Web Size1000 MmMax Machine Speed For 3 Side Seal75 Pcs/min For 200 Mm LengthMax Machine Speed For Standup40 Pcs/min 200 MmUnwind Motor - 3 HpSynchronised To Main DriveCooler FunctionPneumaticCutter FunctionPneumaticSealer Function Side/bottomPneumaticMachine ColorVip Blue & Swan WhiteWeight Of Machine2600 Kgs. AproxUnwind Drive - Vfd3.0 Hp.Servo Motor10 NmElectrical Load38 K.w. AproxSealing Area Bottom Seal10 & 15 Mm With M/c.Sealing Area Side Seal5-15 MmZipper Size15 Mm WidthFAQs of Stand Up Pouch Making Machine:

Q: What is the material used for the construction of the Stand Up Pouch Making Machine?

A: The Stand Up Pouch Making Machine is constructed using stainless steel, ensuring durability and resistance to corrosion.Q: What control system does the Stand Up Pouch Making Machine use?

A: The machine operates with a PLC Control system for accurate and efficient performance.Q: Is the Stand Up Pouch Making Machine automatic or manual?

A: The machine is fully automatic for seamless operations.Q: What type of auxiliary packaging machine is integrated with this product?

A: The auxiliary packaging machine type is a sterilizer to enhance hygiene in pouch production.Q: What is the drive type of the Stand Up Pouch Making Machine?

A: The machine is powered by an electric drive type for reliable and consistent output.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in थैली बनाने की मशीन Category

सेंटर सील कम थ्री साइड सील पाउच मशीन

माप की इकाई : यूनिट/यूनिट

फ़ीचर : हैवी ड्यूटी मशीन, टिकाऊ, अत्यधिक कुशल

ड्राइव टाइप : इलेक्ट्रिक

स्वचालित ग्रेड : ऑटोमेटिक

न्यूनतम आदेश मात्रा : 1

टाइप करें : पैकेजिंग लाइन

थ्री साइड सील पाउच मशीन

माप की इकाई : यूनिट/यूनिट

फ़ीचर : हैवी ड्यूटी मशीन, टिकाऊ, अत्यधिक कुशल

ड्राइव टाइप : इलेक्ट्रिक

स्वचालित ग्रेड : ऑटोमेटिक

न्यूनतम आदेश मात्रा : 1

टाइप करें : पैकेजिंग लाइन

सेंटर सील पाउच मशीन

माप की इकाई : यूनिट/यूनिट

फ़ीचर : हैवी ड्यूटी मशीन, टिकाऊ, अत्यधिक कुशल

ड्राइव टाइप : इलेक्ट्रिक

स्वचालित ग्रेड : ऑटोमेटिक

न्यूनतम आदेश मात्रा : 1

टाइप करें : पैकेजिंग लाइन

स्टैंड अप पाउच मशीन

माप की इकाई : यूनिट/यूनिट

फ़ीचर : हैवी ड्यूटी मशीन, टिकाऊ, अत्यधिक कुशल

ड्राइव टाइप : इलेक्ट्रिक

स्वचालित ग्रेड : ऑटोमेटिक

न्यूनतम आदेश मात्रा : 1

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें