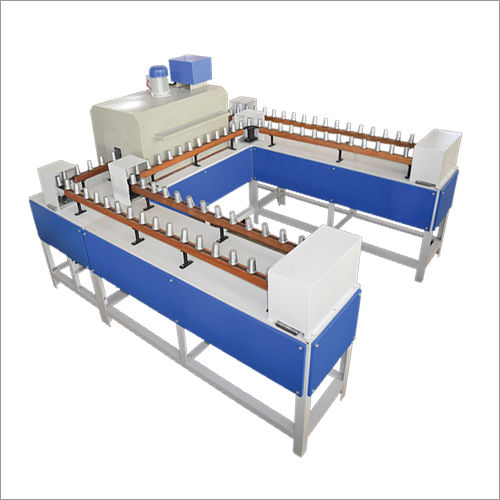

Inspection Machine (Doctoring Machine)

Inspection Machine (Doctoring Machine) Specification

- Product Type

- Labeling Machine

- Material

- Mild Steel

- Application

- Industrial

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Power Source

- Electric

- Feature

- High Performance, ECO Friendly, High Efficiency

Inspection Machine (Doctoring Machine) Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 15-20 Days

About Inspection Machine (Doctoring Machine)

Specification Minimum web width 60mm Maximum web width 300mm Minimum label width 50mm (tube form) Maximum label width 300mm (tube form) Maximum machine speed 0-200 meters/min Glue less tube detector Air bubble burst system Unwind tension control Servo motor with controller Bi directional run By Fault detection or manual defect switch Rewinder tension control Servo motor with auto tension controller Maximum roll diameter 600mm Web aligner unit Fitted with linear guide way in rail Web aligner controller Stepper actuator with FMS OR E+L sensor Core size unwind & rewind 3" Air shaft Speed controller By touch screen monitor and PLC Stroboscope to check print Synchronized to machine speed with sensorFAQs of Inspection Machine (Doctoring Machine):

Q: What materials are used in the construction of the Inspection Machine (Doctoring Machine)?

A: The Inspection Machine (Doctoring Machine) is constructed using mild steel for durability and reliability.Q: What type of power source is required for the Inspection Machine (Doctoring Machine)?

A: The machine operates using an electric power source.Q: Is the Inspection Machine (Doctoring Machine) automatic or manual?

A: The Inspection Machine (Doctoring Machine) is fully automatic for enhanced efficiency.Q: What are the primary features of the Inspection Machine (Doctoring Machine)?

A: The primary features include high performance, high efficiency, and eco-friendliness.Q: What kind of applications is the Inspection Machine (Doctoring Machine) suitable for?

A: The machine is designed for industrial applications.Q: What drive type is used in the Inspection Machine (Doctoring Machine)?

A: The machine features an electric drive type for smooth and efficient operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Shrink Label Making Machines Category

Shrink Sleeve Seaming Machine

Minimum Order Quantity : 1 Unit

Product Type : Labeling Machine

Power Source : Electric

Automatic Grade : Automatic

Application : Industrial

PVC Preform Cap Making Machine

Minimum Order Quantity : 1 Unit

Product Type : Labeling Machine

Power Source : Electric

Automatic Grade : Automatic

Application : Industrial

Drive Type : Electric

PVC Profile Pouch Machine ( 'U' Cut Machine)

Minimum Order Quantity : 1 Unit

Product Type : Labeling Machine

Power Source : Electric

Automatic Grade : Automatic

Application : Industrial

Drive Type : Electric

Gluing and Rewinding PVC Shrink Label Making Machine

Minimum Order Quantity : 1 Unit

Product Type : Labeling Machine

Power Source : Electric

Automatic Grade : Automatic

Application : Industrial

Drive Type : Electric

Send Inquiry

Send Inquiry Send SMS

Send SMS